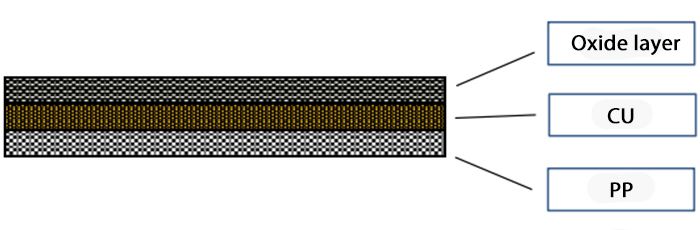

- Total thickness: (10μm to over 100μm) with a tolerance of ±3μm

- PP layer thickness: (≥4μm) + copper layer (≥0.1μm)

- Tensile strength: ≥30Mpa

- Width: 0.5mm to 990mm

- Elongation rate: ≥30% minimum

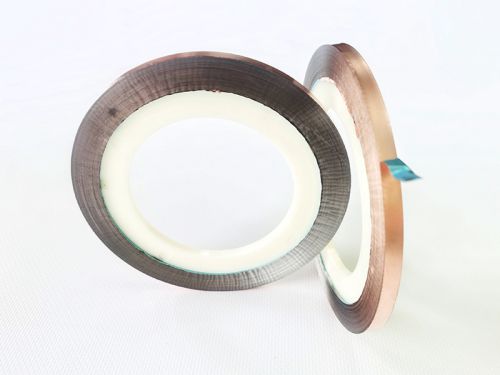

- Packaging: rolls (D30), sheets, 76mm removable rolls, inverted cone packaging

Copper metallized PP film

Copper vapor-deposited onto film in a vacuum. High dielectric, excellent insulation, heat resistance.

Polypropylene (PP)

Semi-crystalline thermoplastic, strong impact resistance, robust mechanical properties, and resistance to various organic solvents and acid-base corrosion.

- Suitable for uneven surfaces

- Offers high flexibility

- Easy to use

- Flame retardant materials

- Thermal conductive materials

- Data transmission cable

- EMI shielding

EMI solutions include three main approaches: electromagnetic interference shielding, printed circuit board grounding, and electromagnetic interference absorption.

- Electromagnetic Interference Shielding involves blocking electromagnetic noise and attenuating cable-collected noise. It uses high-reflectance materials (usually low-resistance metals) to encase or seal openings in target devices for EMI and EMS solutions.

- Printed Circuit Board (PCB) Grounding refers to grounding electronic equipment electrically to prevent electric shock, treating the Earth as a massive conductor at zero electric potential. Two grounding methods are employed: frame grounding and signal grounding on PCBs.

- Electromagnetic Interference Absorption (EMI Absorption) utilizes magnetic loss, dielectric loss, and conduction loss to convert radio wave energy into thermal energy. EMI absorbers have a wide range of applications.

Polyester Film Tape (PET Tape)

Polyester Film Tape (PET Tape) Shielding Laminates

Shielding Laminates Vacuum Metallized Films & Fabrics

Vacuum Metallized Films & Fabrics