FAQ

We are a specialized manufacturing company focused on the research, development, production, and sale of ultra-thin and extremely fine shielding materials.

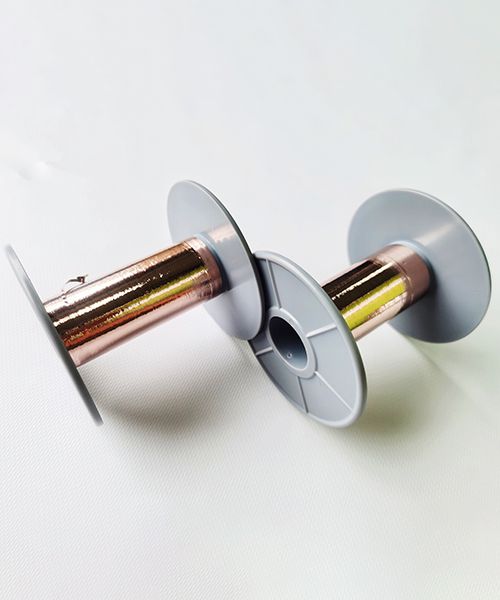

Our company's primary products include tapes laminated copper foils, tapes laminated aluminum foils, and metallized conductive fabrics, among others.

Since our establishment in 2012, we have accumulated over a decade of experience in research and development, manufacturing, and sales for shielding materials.

Our production facilities include five laminators, five large sheet cutting machines, 32 slitting and winding machines (with 24 heads), and 32 single-head rewinding machines.

Our processing workshop has an annual production capacity of up to 5 billion meters.

We have a wide range of materials that we can process, including non-metallic materials like PEN, PET, PPS, PP, PI, PTFE, and EPTFE, as well as various metal materials such as aluminum, copper, gold, silver, nickel, tin, indium, and more.

Typically, our products have a width ranging from 0.5 meters to 1.4 meters and lengths between 1000 and 20000 meters per roll.

Copper foil is an extremely thin copper material, which can be categorized into two types based on the manufacturing process: rolled (RA) copper foil and electrolytic (ED) copper foil. Copper foil possesses excellent electrical and thermal conductivity properties and is known for its ability to shield electrical and magnetic signals. It is widely used in the manufacturing of precision electronic components. As modern manufacturing advances, there is a growing demand for thinner, lighter, smaller, and more portable electronic products, leading to broader applications of copper foil.

RA copper foil and ED copper foil have their respective advantages and disadvantages.

- RA copper foil is purer in terms of copper content.

- RA copper foil offers better overall physical performance compared to electrolytic copper foil.

- Both types of copper foil have nearly identical chemical properties.

- In terms of cost, ED copper foil is usually less expensive due to its simpler manufacturing process and the ease of mass production.

- Typically, RA copper foil is used in the early stages of product manufacturing, but as manufacturing processes mature, ED copper foil is often utilized to reduce costs.

Copper ions are highly reactive in the presence of air and can easily react with oxygen ions to form copper oxide. While we treat the surface of copper foil with room temperature anti-oxidation processes during production, this treatment only delays the oxidation of copper foil. Therefore, it is recommended to use copper foil as soon as possible after opening. Unused copper foil should be stored in a dry, light-resistant area and away from volatile gases. The recommended storage temperature for copper foil is approximately 25 degrees Celsius, with humidity not exceeding 70%.

Slightly oxidized copper foil surfaces can be cleaned using an alcohol sponge. However, for long-term or extensive oxidation, a sulfuric acid solution is required to clean and remove oxidation.

Cable taping methods include longitudinal taping and cross taping. Cross taping further divides into traverse taping and diagonal taping. Longitudinal taping is used for core wires where no overall stranding is required, and it does not require flexibility. Traverse taping is a high-speed process with good flexibility.

Films laminated aluminum foil with hot melt adhesive are divided into two types: aluminum/PE shielding films and aluminum/PVE shielding tapes. They use MQ-40 high-molecular-weight polymer as heat-sealing glue, which is non-toxic and eco-friendly and complies with the latest version of the EU RoHS environmental regulations. The other type is self-adhesive film laminated aluminum foil, which uses genuine EAA self-adhesive film, ensuring good heat-sealing bonding effects at lower preheating temperatures and long-term stability.

Copper/PET shielding tapes is primarily used in various fields, such as extremely fine coaxial wires, low-loss antennas (computers), solar cell wires, etc.

EMI solutions include three main approaches: electromagnetic interference shielding, printed circuit board grounding, and electromagnetic interference absorption.

- Electromagnetic Interference Shielding involves blocking electromagnetic noise and attenuating cable-collected noise. It uses high-reflectance materials (usually low-resistance metals) to encase or seal openings in target devices for EMI and EMS solutions.

- Printed Circuit Board (PCB) Grounding refers to grounding electronic equipment electrically to prevent electric shock, treating the Earth as a massive conductor at zero electric potential. Two grounding methods are employed: frame grounding and signal grounding on PCBs.

- Electromagnetic Interference Absorption (EMI Absorption) utilizes magnetic loss, dielectric loss, and conduction loss to convert radio wave energy into thermal energy. EMI absorbers have a wide range of applications.