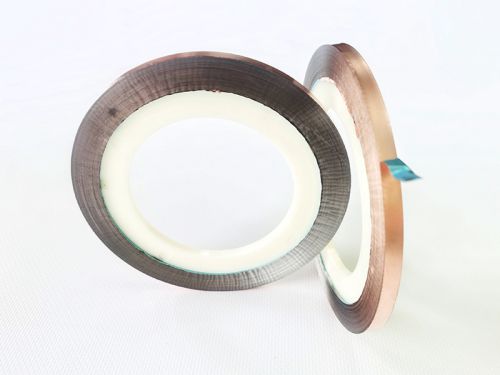

- Vacuum metalizing, also known as vacuum deposition, is the process of physically depositing metal materials onto plastic components within a vacuum chamber. It's a form of physical vapor deposition (PVD) that allows the formation of metal layers on components or substrates, achieved by evaporating metals like aluminum or copper onto non-metallic base materials.

- Metal evaporation occurs within a sealed chamber with a heat source, reaching temperatures of approximately 1500°C (2700°F) under high vacuum conditions. Reduced pressure in the vacuum chamber lowers the boiling point of the metal, causing the liquid metal to transition to a gaseous state. The metal vapor adheres to the substrate, creating metal coatings or decorative layers on films or fabrics. Vacuum metalizing was first used in the 1930s to produce reflective coatings for lenses, expanding to various optical components, streetlights, and automotive headlights. Vacuum metalizing is also used for aluminum coatings, decorative materials, and surface-modifying functional films, including imitation gold plating for cases, creating metal textures on plastics, and coating tools for various mechanical applications.

- Furthermore, as global environmental concerns increase, vacuum metalizing, as an environmentally friendly surface treatment, is gaining attention. This surface treatment is conducted almost entirely in a vacuum chamber, preventing the release of metal vapor into the air.

In addition, vacuum metalizing is essential in the aluminum wire manufacturing and custom parts manufacturing.

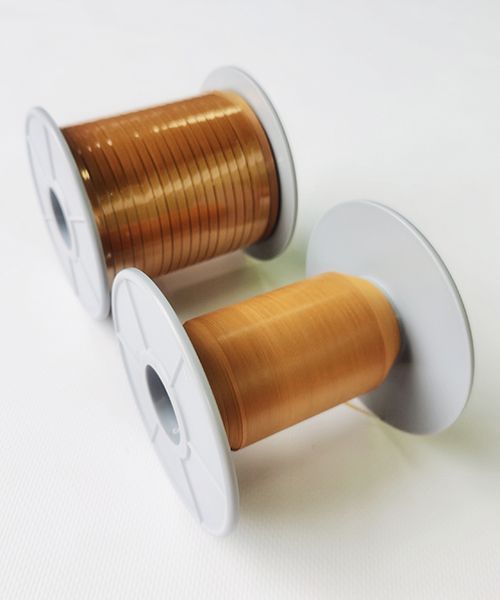

For over a decade, clients have turned to us for our expertise in vacuum metalizing. Our services extend to roll-to-roll applications, allowing us to vacuum-metalize materials such as polyester, polyimide, and fabrics. We have extensive experience in processing various films and fabrics, enabling us to create the vacuum metalized materials our customers need. If you have any inquiries or product intentions related to vacuum metalizing, please feel free to contact us. We look forward to collaborating on your project.

Our vacuum metalizing team includes experienced project managers and engineers. In addition to providing standard vacuum metalizing services, we have a research and development team that develops new coatings and adhesives to add more functionality to vacuum-metalized films. We can ensure efficient delivery to your facility based on your location or end market.

Substrate Pre-Cleaning

Substrate Pre-Cleaning  Metal Coating

Metal Coating  Defect Detection & Cutting

Defect Detection & Cutting  Packaging

Packaging

Parameters (to be supplemented with other customer-concerned parameters)

- Metal Coating Thickness: 20 nanometers to 2μm

- Substrate: Various material film roll-to-roll laminating and vacuum metallization (metal, non-metal)

- Available Sizes: 500mm to 1200mm

- Thickness Range: ≥2μm

-

- Laminating Our laminating capabilities enable the creation of multi-layered structures using various flexible base materials. View More

-

- Vacuum Metalizing Vacuum metalizing, also known as vacuum deposition, is the process of physically depositing metal materials onto plastic components within a vacuum chamber. View More