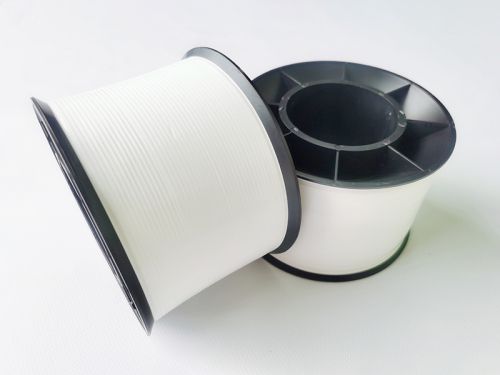

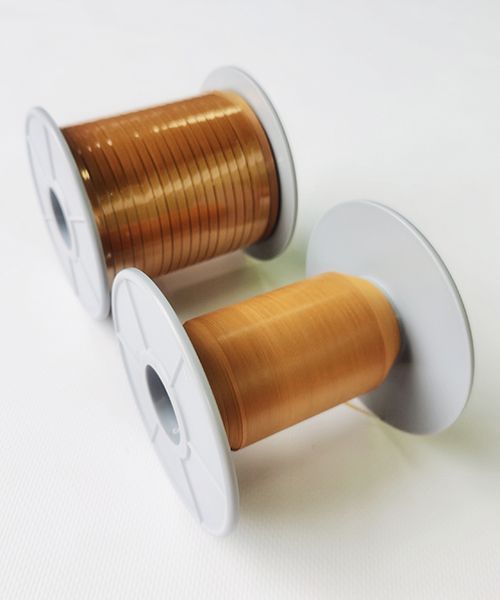

Our laminating capabilities enable the creation of multi-layered structures using various flexible base materials. The specific base material used depends on your project's requirements. As a professional company with over 10 years of laminating experience, we empower our customers to obtain laminated materials made from a wide range of materials. In addition to these base materials, we feature film laminates, producing shielding laminates up to 990mm wide. Laminating can also be combined with our vacuum metallization expertise to produce truly unique products.

Common film laminating structures we can produce for you include

- Metal & non-metal laminates

- Non-metal & non-metal laminates

- Metal & metal laminates

Since our inception, we have worked with our clients to develop and customize various types of products across multiple industries. We also collaborate with you in the strictest confidentiality to fully understand the critical performance parameters of your required products. We are committed to taking your product design from concept to full commercialization through systematic and effective methods.

The successful bonding of two or more base materials to precise specifications has driven our laminating business. We specialize in manufacturing roll-to-roll film laminated metal foils on various flexible roll materials. Our expert team is personally involved in customizing solutions, ensuring our customers get the laminating structures they desire. The adhesives we use can withstand extreme conditions and can be applied to a variety of different materials.

Laminating Adhesive to Substrate

Laminating Adhesive to Substrate  Curing & Drying

Curing & Drying  Defect Detection & Cutting

Defect Detection & Cutting  Packaging

Packaging

Parameters (to be supplemented with other parameters of customer concern)

- Substrate: Various material film roll-to-roll laminating and vacuum metallization (metal, non-metal)

- Production Width: 500mm to 990mm

- Thickness Range: 10μm and above

Types

- Multi-layer laminated materials

- Overlapping

- Room temperature lamination

- Heat lamination

- Solvent-free lamination

-

- Vacuum Metalizing Vacuum metalizing, also known as vacuum deposition, is the process of physically depositing metal materials onto plastic components within a vacuum chamber. View More

-

- Laminating Our laminating capabilities enable the creation of multi-layered structures using various flexible base materials. View More