- Specialized Lamination Processing

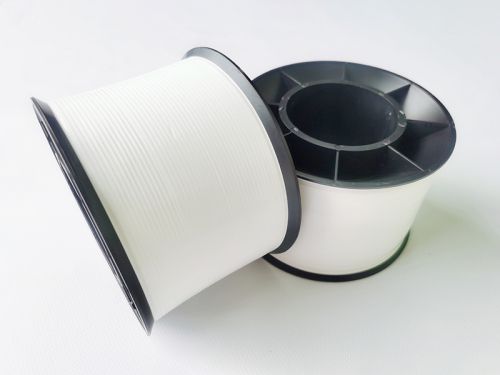

We excel in the laminating processes of signal shielding materials and insulating materials for diverse cable applications. - Custom Material Lamination

Tailored to our buyers' needs, we combine different plastic materials such as PET film, PP film, and PI film, along with various metal materials like copper and aluminum films. This allows us to create double-layer, triple-layer, and even multi-layer laminates. - Versatile Solutions

Our lamination process empowers us to produce shielding laminates with varying thicknesses and widths, ensuring they align with customer requirements for fire resistance, waterproofing, and signal shielding.

FAQs

What is the difference between metal materials and shielding laminates?

Shielding laminates, unlike metal, are non-conductive at their core. While metals like copper are conductive by nature, shielding laminates formed with non-metals excel as insulating or signal shielding materials, which do not respond to electric fields and resist the flow of electric charge.

What are the basic principles of shielding laminates?

Shielding laminates are composed of at least two materials, and the combined performance of these materials exceeds that of their individual components. In our context, we refer to shielding laminates consisting of both metals and non-metals, typically involving the combination of PET, PP, PI, PPS, PTFE with metals like copper and aluminum.

What are the four main types of shielding laminates?

Shielding laminates are typically categorized based on the type of matrix material used. The four primary categories of shielding laminates are Polymer Matrix Composites (PMC), Metal Matrix Composites (MMC), Ceramic Matrix Composites (CMC), and Carbon Matrix Composites (CAMC).

What are metal shielding laminates?

Metal shielding laminates are produced by continuously bonding two thin metal sheets or natural metal films to one side of a thermoplastic core material. These core materials form sheets that are lighter in weight, easy to manufacture, flat, and durable.

Advantages of shielding laminates

- High dimensional accuracy in molding

- Low post-molding shrinkage

- Chemical resistance

- Design flexibility

- Durability

- Outstanding mechanical properties

- Excellent thermal stability

- Lighter weight compared to metals

- Excellent electrical insulating properties