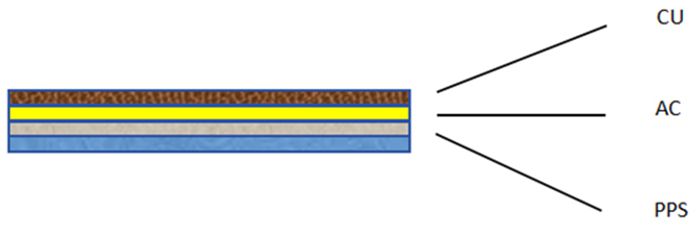

- Total Thickness: (10μm to over 100μm) ±3μm

- PPS Layer Thickness: (≥4μm) + Copper Layer (≥0.1μm)

- Tensile Strength: ≥30Mpa

- Width: 0.5mm to 990mm

- Elongation: ≥30%Min

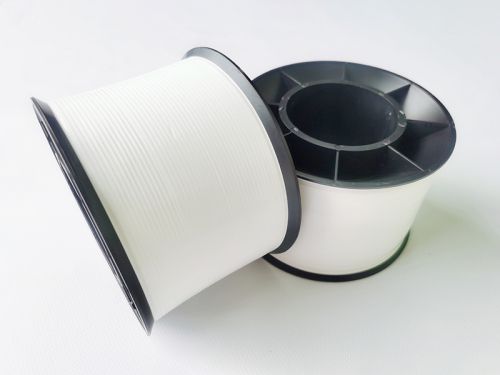

- Packaging: rolls(D30), sheets, 76mm removable rolls, inverted cone packaging

Copper/PPS shielding tape is an electrical insulation tape using PPS film with excellent chemical and heat resistance, in which PPS plastic (Polyphenylene Sulfide) is a high-performance thermoplastic engineering plastic known for its outstanding features, including high-temperature resistance, corrosion resistance, and superior mechanical properties.

- Ease of Coating

- Flame retardant, radiation resistance, and thermal insulation.

- High-temperature insulation

- High adhesion strength and dielectric strength

- Outstanding voltage resistance and tensile strength

- Perfect balance of electrical, chemical, and physical properties

- Dimensional stability

PPS film can maintain its dimensions and shape even when exposed to high temperature and high humidity thanks to its minimum molding contraction rate and thermal expansion. - Electrical properties

PPS film has superior electrical insulation properties, making it suitable for applications needing to exposure to high humidity, high temperature environments. - Chemical resistance

One of the significant advantages of PPS is its outstanding chemical resistance. PPS exhibits strong resistance to a variety of chemicals, such as acids, bases, solvents and fuels. - Mechanical properties

PPS film has high strength and high rigidity with minimum degradation at high temperatures. Additionally, it has excellent resistance to creep and fatigue, thus making it can bear heavy loads and resist deformation.

- Thin and heat-resistant parts for fastening and electrical insulation

- Used in TAB bonding (tape automatic bonding), heat-resistant films, etc

- Flame retardant materials

- Thermal insulation materials

- Data transmission cable

- EMI shielding

RA copper foil and ED copper foil have their respective advantages and disadvantages.

- RA copper foil is purer in terms of copper content.

- RA copper foil offers better overall physical performance compared to electrolytic copper foil.

- Both types of copper foil have nearly identical chemical properties.

- In terms of cost, ED copper foil is usually less expensive due to its simpler manufacturing process and the ease of mass production.

- Typically, RA copper foil is used in the early stages of product manufacturing, but as manufacturing processes mature, ED copper foil is often utilized to reduce costs.

Polyester Film Tape (PET Tape)

Polyester Film Tape (PET Tape) Shielding Laminates

Shielding Laminates Vacuum Metallized Films & Fabrics

Vacuum Metallized Films & Fabrics